Shims – Facts, Applications and Manufacturing

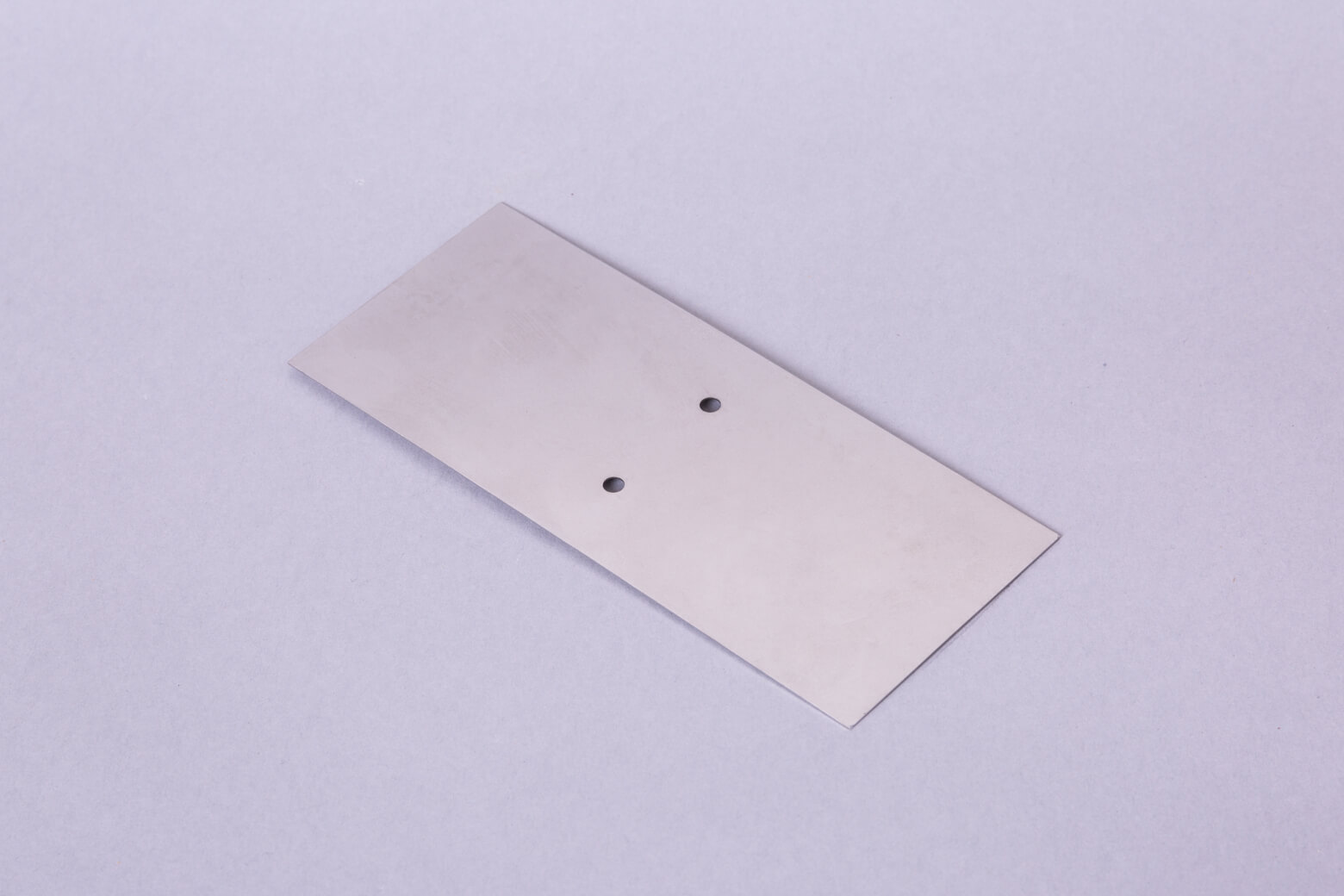

Shims are an important component in the industry and are used to compensate for tolerances during assembly and manufacturing. They are thin, flat washers made of metal, plastic or other materials, placed between two surfaces to adjust the distance, create stability and ensure correct fit.

Here you can find facts about shims, how they are manufactured and their most common applications.

What are shims?

Shims are thin spacers used to adjust tolerances in various products and machines. They are usually only a few millimeters thick and made of materials such as steel, stainless steel, aluminum, brass, plastic or rubber. The shape can vary – the most common are rectangular or circular washers. There are also peelable (laminated) shims and shims made of welded blades where you can remove layers to achieve the exact required dimension.

What does it mean that shims compensate for tolerances?

In manufacturing and assembly, small dimensional variations, so-called tolerances, always occur. Shims are used to even out these variations and ensure that parts fit perfectly together. By placing a shim between two surfaces, you can adjust the distance, correct misalignments and create stability. In this way, shims compensate for the variations that would otherwise cause problems such as play, vibrations, leakage or reduced performance.

With the right shim in the right thickness, you achieve an exact fit and can extend the service life of both machines and components.

How are shims manufactured?

Material selection: First, the material is chosen based on requirements for durability, weight, cost and corrosion resistance. Common materials include stainless steel, aluminum, brass and plastic.

Cutting: The material is processed using CNC machines, laser cutting or shears to achieve the correct dimensions with high precision.

Stamping: For serial production, stamping machines are used to form shims efficiently and with accuracy.

Grinding: The surface is ground to remove irregularities and adjust thickness.

Thickness adjustment: If necessary, thickness can be fine-tuned by grinding or chemical etching.

The manufacturing method varies depending on material, tolerance requirements and application. Read more about manufacturing here.

Applications of shims

Shims are used to even out differences, adjust height, align misaligned surfaces and compensate for wear. In industry, they are commonly used in machines, bearings, engines and other equipment where precision is crucial. By placing a shim between two surfaces, you can achieve exact fit and extend the service life of components.

How to choose dimensions?

To choose the right shim, measure the distance between surfaces and calculate the required adjustment. Then select a shim with the correct thickness and dimensions to achieve optimal fit and function.

Handling of shims

Since shims are often thin and delicate, they should be handled with care. They must not be bent or damaged and should be stored in a dry and clean environment to avoid corrosion. At Empiro, we also offer laser marking, ink marking and etching for easy identification and organization of shims.

Different types of shims

There are several types of shims, adapted for different needs. Here are some common types:

Laminated shims

Laminated shims consist of several layers of metal laminated together. By removing layers, the thickness can be adjusted with high precision. They are often used in the aerospace industry as well as in machines exposed to vibrations, where exact tolerances are critical.

Shims for bearings

Shims for bearings are used to adjust bearing clearance. Correct clearance is important for optimal function and service life. These shims are made from strong materials such as steel and have high tolerance levels to ensure perfect fit.

Custom-made shims

Do you need shims in unique shapes, materials or dimensions? At Empiro we offer custom-made shims tailored to your specific needs.

Shims in different materials

Shims are available in many different materials. Common options include stainless steel, aluminum and brass. The choice of material depends on the application and the requirements placed on the shims, such as durability, corrosion resistance and cost. Stainless steel is usually the most durable option and is often used in demanding environments exposed to moisture or corrosive substances. Aluminum is a lighter and more economical alternative, suitable for less demanding applications. Brass and copper are often used in applications where conductive properties or an aesthetically appealing surface are important. The choice of material can also affect the tolerances that can be achieved, which is why it is important to select the right material for the specific application.

Contact us for expert advice on shims

At Empiro, our team of shim experts is ready to help you find the perfect solution for manufacturing, dimensions, tolerances, and materials. Whether you need guidance on selecting the right shim or customizing a solution, don’t hesitate to get in touch with us today.